Metallography

-

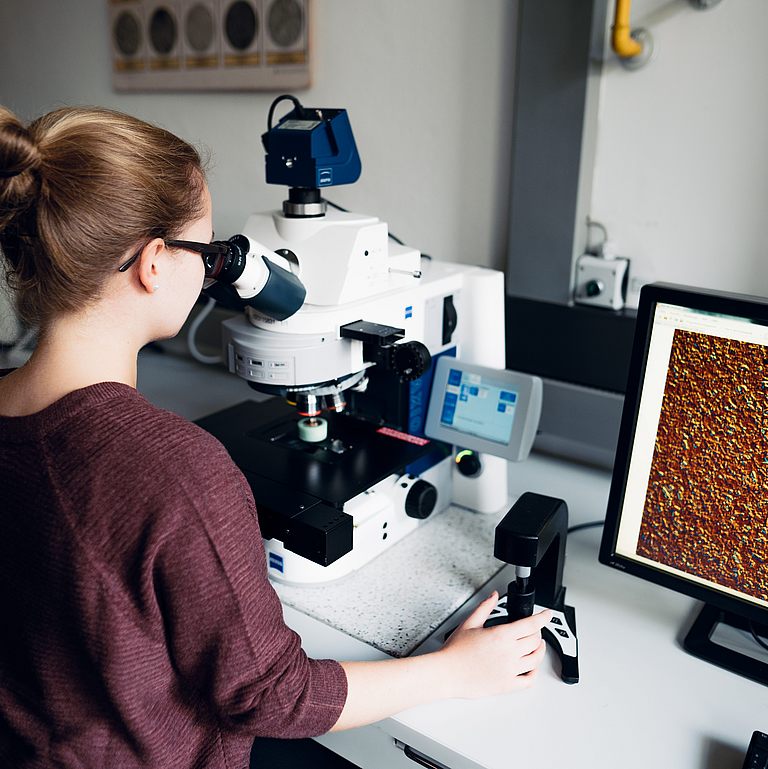

Stereo and reflected light microscopy with digital image analysis

Zeiss Axio Imager.M2m

Purpose: Optical analysis, image acquisition, phase analysis, particle detection.

How it works:

A stereo microscope is a special light microscope in which a separate beam path is provided for both eyes. Both eyes therefore see the specimen from a slightly different angle, so that a "stereo effect", i.e. a spatial image impression, occurs. Stereomicroscopes usually work with magnifications below 100:1 because, due to the rapidly decreasing depth of field at high magnifications, a spatial image is only meaningful at these comparatively low magnifications.(Source)

Light microscopes [...] are microscopes that produce highly magnified images of small structures or objects using light. Magnification is achieved according to the laws of optics by utilizing light refraction on glass lenses. In order to recognize structures in the image produced, the image must contain sufficient contrast, which is almost non-existent in many biological objects such as tissue sections or small aquatic organisms. The 'typical' microscopic technique for such objects is brightfield microscopy, in which contrast is induced by colored or dark structures in the transilluminated specimen, enhanced if necessary by additional artificial coloring of the object. For colorless specimens, contrast can also be induced with special illumination techniques by converting differences in optical density (refractive index) into differences in brightness. This is done in dark-field microscopy, phase-contrast microscopy, and differential interference contrast (DIC) or the oblique illumination method used in the early days of microscopy. Differences in the polarization behavior of the specimen are used in polarized light microscopy.(Source)

-

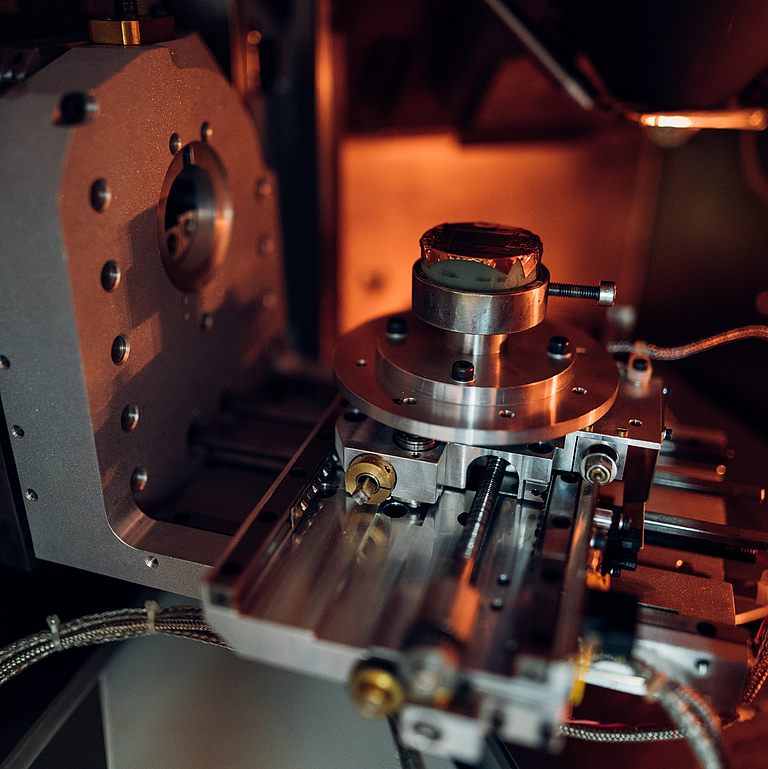

Small load hardness tester

Bühler Micromet 5103

Microhardness is a material parameter for various materials. In the case of metals, the microhardness system is used to investigate hardness values for individual microstructural components, in contrast to macrohardness, which is used to determine a hardness value for the entire metallic matrix of a material. The Vickers hardness testing method is usually used for this purpose.(Source)

Test method: Vickers

Load range: 0.01-1 kg (10 gf, 25 gf, 50 gf, 100 gf, 200 gf, 300 gf, 500 gf, 1000 gf)