Material testing

-

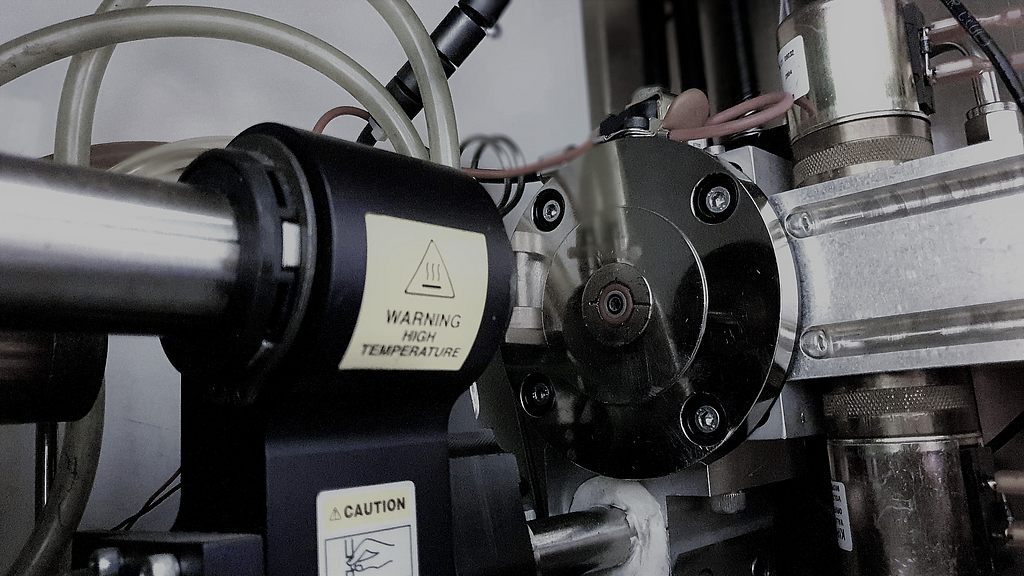

Umformsimulatoren

Temperature range 20 °C - 1400 °C Any number of forming steps Max. Heating rate (full specimen) 100 K/s or 50 K/s Max. quenching rate (hollow specimen) 100-200 K/s Quenching speed (hollow sample) 100-200 K/s Cooling media N2, Ar, He Temperature measurement with up to 3 thermocouples and pyrometer (torsion) Negative pressure up to 5-10-5 mbar

DIL 805 A/D TTS 820Z TTS 820F TTS 820T Quenching/Deformation Cylinder upset Flat upsetting Torsion Specimen size in mm d = 5 ; l = 10 d = 5 ; l = 10 l = 15 ; h = 2-8 ; b = 10 d = 6 ; lmax = 30 max. U-speed in mm/s 125 1000 1000 1800 rpm max. φ* in 1/s 12,5 100 100 10 max. φ 1,2 1,2 2 10 max. D-force in kN 25 100 100 75 L-measurement method LVDT LVDT/Laser LVDT/Laser incremental -

Universal testing machines

Universal testing machine UTS 250 kN Tests Compression and tensile test, bending test Specimen shapes flat and round Testing speeds 0.08 mm/min to 500 mm/min Evaluation Software supported, ASCII export Universal testing machines MAN 200 kN, 1000 kN Tests Compression and tensile test, bending test Specimen shapes flat and round Evaluation Software supported, ASCII export Universal testing machine 100 kN Tests Compression and tensile test, cold tensile test, hot tensile test up to 850 °C Specimen shapes flat and round Evaluation Software supported, ASCII export -

Sheet metal and strip testing machines

Sheet and strip testing machine ERICHSEN 129/D Specimen width 0 - 180 mm Specimen thickness 0 - 2 mm (Erichsen test), 0 - 1.2 mm (cell pull) Hold-down pressure max. 2500 kN Punch pressure max. 6000 kN Drive electro-hydraulic Sheet and strip testing machine ERICHSEN 145/D specimen width 0 - 190 mm Drawing die max. ∅ 75 mm Round blank max. ∅ 180 mm Cup draw Ø drawing punch 33/75 mm, Ø round head 50 - 80 mm / ∅ 180mm Drawing punch stroke max. 130 mm Sheet holding force max. 110 kN Compressive force max. 600 kN Drawing speed up to 300 mm/min Motor 4 kW