Chemical analytics

-

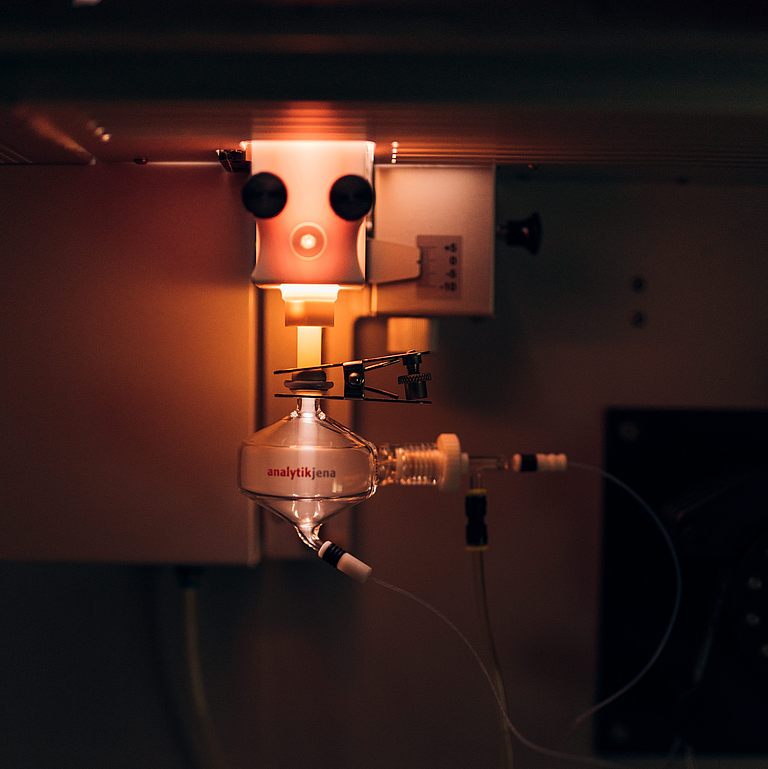

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

Analytik Jena PlasmaQuant PQ 9000 Elite

Physical principle: After digestion of the sample substance, the resulting solution is atomized and ionized in an inductively coupled argon plasma. The released atoms and ions are excited by the high energy of the Ar plasma. The radiation produced after excitation is decomposed in a spectrometer and its intensity is measured. From this, the element concentration can be determined after prior calibration. Here the signal acquisition is done sequentially (each element/line individually), but with a spectral resolution of 1:100000 (2pm at 200nm - market standard is about 5-8pm at 200nm), which is very advantageous for complex matrices (Fe-, W-, Nb- or REE-based).

Application: Determination of metals in solutions and solids after digestion. All metals and transition metals (incl. B), as well as P, S and I can be measured. The technique is mature, fast and very sensitive, but usually not as cost effective as AAS.

-

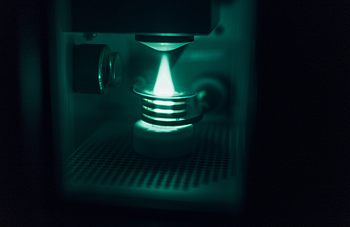

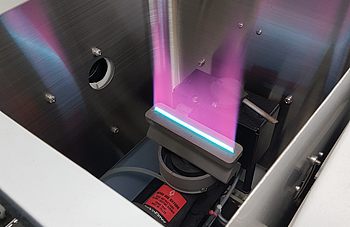

Glow Discharge Spectrometry (GD-OES)

Leco GDS-850A

Purpose: Material analysis (qualitative and quantitative); depth profile up to 100µm.

Physical principle: A glow discharge is built up between the sample surface and a hollow anode at an Ar pressure of a few hundred Pascal. The Ar+ ions generated in this discharge are accelerated by a potential of about 1000 V to the sample surface where they knock out metal atoms ("sputtering"). The metal atoms thus produced also enter the glow discharge and are excited there. The radiation produced after excitation is decomposed in a spectrometer and its intensity is measured. From this, the composition of the sample can be determined after prior calibration.

Application: Determination of sample composition ("bulk analysis"), depth profile measurement qualitatively and quantitatively down to 100 µm depth with a depth resolution of 5 - 10 % of the absolute depth reached in the layers near the surface. In principle all elements are measurable, incl. H, O, N, C, P, S, halogens and noble gases (exception Ar, as it is the plasma gas); quantifiable are only those elements in matrices for which calibration samples can be obtained or produced. Due to the high frequency option, non-conductive surfaces can also be analyzed.

-

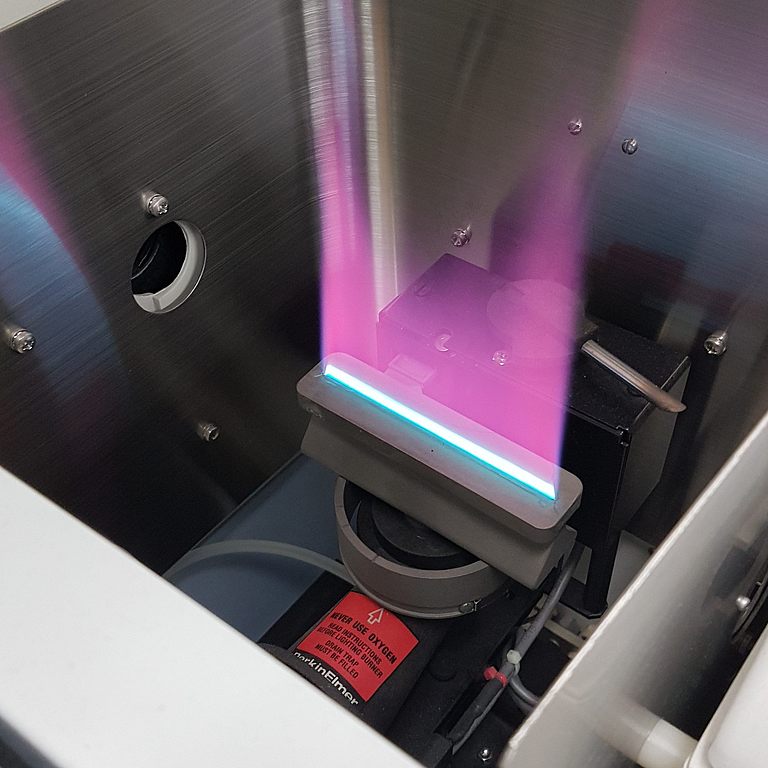

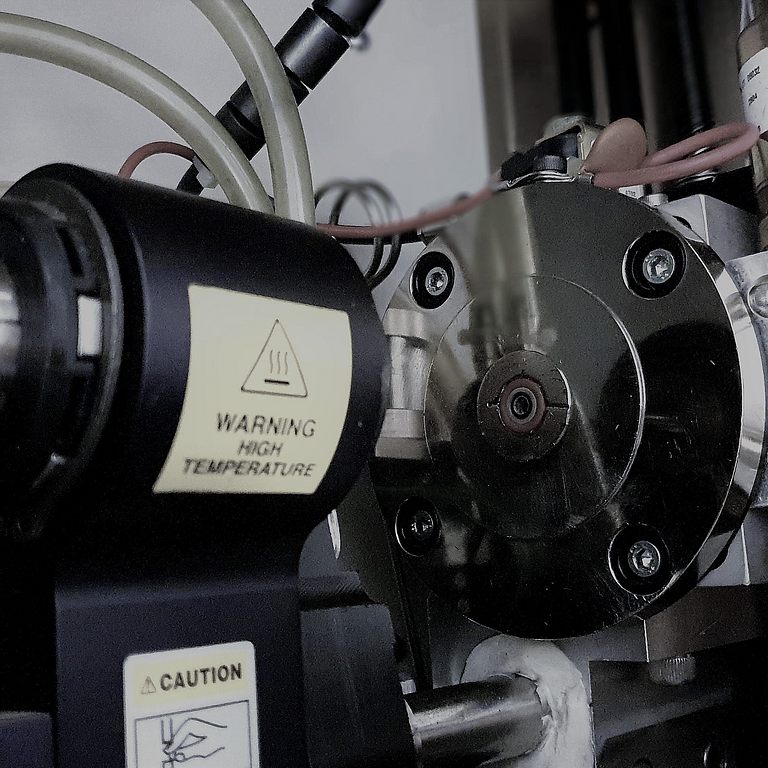

Flame Atomic Absorption Spectrometry (F-AAS)

PerkinElmer AAS Analyst 300

Purpose: chemical analysis of metals in solutions

Physical principle: After digestion of the sample substance, the resulting solution is atomized into a flame. Radiation from an element-specific hollow cathode lamp is passed through this flame. The released atoms absorb their characteristic wavelength and from the absorption signal thus obtained, the element concentration can be determined after prior calibration.

Application: Determination of metals in solutions and solids after digestion. All metallic elements (exceptions are Ce and the radioactive elements) can be measured. The technique is mature, fast and inexpensive, but generally not as sensitive as ICP-OES.

-

Combustion analysis C/S

Leco CS-230

Analysis of the elements carbon (C) and sulfur (S)

Element Detection limit* Carbon 13-20 ppm Sulfur 4 ppm *Matrix and sample dependent

High frequency combustion of the metal samples takes place at >2300 °C in a pure oxygen atmosphere. During combustion, the released carbon components are oxidized to CO/CO₂ and sulfur components to SO₂. Dust and water are subsequently filtered out of the combustion gas. The combustion gases are passed in the carrier gas stream (oxygen) to the corresponding infrared sensing elements.(Source)

-

Carrier gas hot extraction N/O

Rosemount NOA-5300

Analysis of the elements nitrogen (N) and oxygen (O)

Element Detection limit* Oxygen 4-20 ppm Nitrogen 4-35 ppm *Matrix and sample dependent

For the analysis of the elements O and N, the metal sample is thermally decomposed. The metal sample is heated in a graphite crucible in the furnace. Temperatures of up to 3000 °C can be reached here. Helium is used as the carrier gas. The released gases, whereby the oxygen O reacts with the carbon C of the graphite crucible to form carbon monoxide CO, flow through various stations (catalysis, absorber, etc.) of the measuring system with the aid of the carrier gas flow and are detected in the corresponding measuring cells.

In an infrared measuring cell, the oxygen content is determined via the CO content. The molecular nitrogen is measured with a thermal conductivity cell.(Source)

-

Spectrophotometer

VWR UV-3100PC

The spectrophotometer VWR UV-3100PC is a single-beam spectrophotometer with a wavelength range of 190-1100 nm and a spectral bandwidth of 2 nm. It has a PC connection, the possibility of a spectra recording as well as the ability to record a time-dependent reaction course.

Substances can be determined that cannot be measured with atomic spectrometric methods, or only with great effort. Furthermore, organic compounds can also be determined. The main purpose here, apart from educational purposes, is the determination of anions, such as fluoride, and a fallback function in the event of instrument failure in the field of instrumental analysis.

Physical principle

Many chemical compounds interact with electromagnetic radiation whose wavelength is in the range of near UV and visible light. By measuring the attenuation of the radiation intensity at a specific and preferably monochromatic wavelength characteristic of the chemical compound, this compound can be quantified. The basis for this is Bouguer-Lambert-Beer's law. By calibration with defined concentrations, the spectral absorption coefficient of the compound to be determined can be determined.

Chemical principle

Since many inorganic compounds do not have a high spectral absorption coefficient by themselves, they are converted into a compound that has a high spectral absorption coefficient. In the case of cations, this is very often chelate complexes. In a few cases, it is also possible to take advantage of a decolorizing effect of an analyte on an absorbable compound. An example of this is the determination of fluoride by decolorization of an Al-aluminone complex.

-

Potentiometric titrator

SI Analytics TitroLine 7750

In potentiometric titration, a continuous measurement of the electromotive force is carried out with the aid of a measuring chain consisting of an indicator electrode and a reference electrode. The indicator electrode must respond to the substance to be analyzed, while the potential of the reference electrode must not change. Nowadays, such electrodes are usually commercially available as "combination electrodes".

During the addition of the dimensional solution, the change in electromotive force is recorded and the end point of the titration is determined from the resulting titration curve. Depending on the analyte and the conditions, the titrator can perform both a dynamic and a linear (monotonic) titration.

Neutralization, redox, precipitation and complexation titrations can be carried out using the appropriate indicator electrodes. Furthermore, the titrator offers the possibility of indexing a titration biamperometrically or also photometrically.

The main field of application is the determination of major and minor constituents in alloys, ores and aggregates, e.g. Mn in FeMn and high manganese steels, Cr in FeCr and high alloy steels or Fe in Fe ores.

-

Pressure digestion with heating block thermostat

Berghof Bezeichnung DAB-2

Open acid digestions often have a high time requirement, since the maximum temperature that can be reached depends on the boiling point of the acid used. This circumstance can thwart successful digestion and thus analysis for very resistant materials. Therefore, closed digestion systems are necessary for resistant materials. Furthermore, closed vessels prevent the loss of volatile compounds that may be generated during the course of a digestion.

The system uses a 50mL TFM™ PTFE liner, which is tightly sealed by a steel pressure vessel. It reaches a maximum temperature of 250 °C and a maximum pressure of 200 bar and can run digestions almost indefinitely. This allows even very resistant sample materials (such as SiC or corundum) to be digested. Most digestions are completed in a few hours.

The block thermostat has 6 stations, so that a maximum of 6 digestions can be performed in parallel.