The teaching of foundry technology at the university covers a wide range of topics relating to the production and processing of metals and alloys using casting processes.

In the lectures, students are taught basic knowledge of materials, thermodynamics, fluid mechanics and materials science. These fundamentals are crucial to understanding the complex processes that occur when casting metals. Students will learn how to select the right metals and alloys for specific applications and how to design the molds and dies to produce high quality castings.

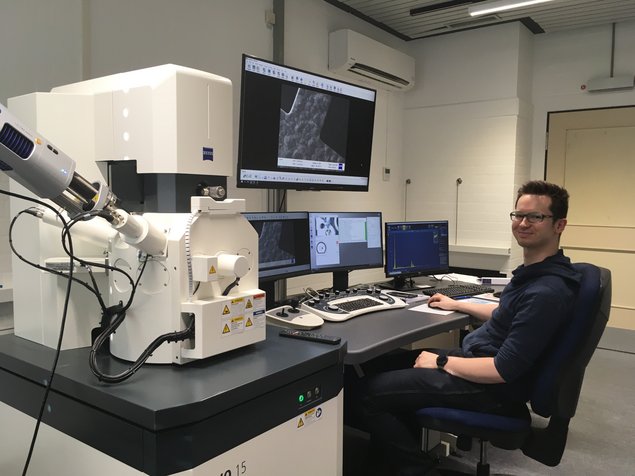

An important part of teaching foundry technology is hands-on experience. Students have the opportunity to participate in real casting processes in the university's laboratories and put their theoretical knowledge into practice. They learn how to operate the molding equipment, prepare the molten metal and cast the molds professionally. They are familiarized with the various casting processes, such as sand casting, gravity die casting and die casting.

In addition, advanced topics such as the simulation of casting processes, quality assurance and control as well as the development of new casting alloys and processes are also covered in the foundry technology course. Students are encouraged to participate in research projects and contribute their own ideas and innovations.

Graduates of the Foundry Technology course have good career prospects in a wide range of industries, including automotive, aerospace, mechanical engineering, power engineering and many others. They work in foundries, research institutes, development laboratories or in consulting.

The teaching of Foundry Technology at the University places great emphasis on providing students with in-depth knowledge, practical experience and innovative thinking. Students are encouraged to develop their potential and contribute to the advancement of this exciting field.