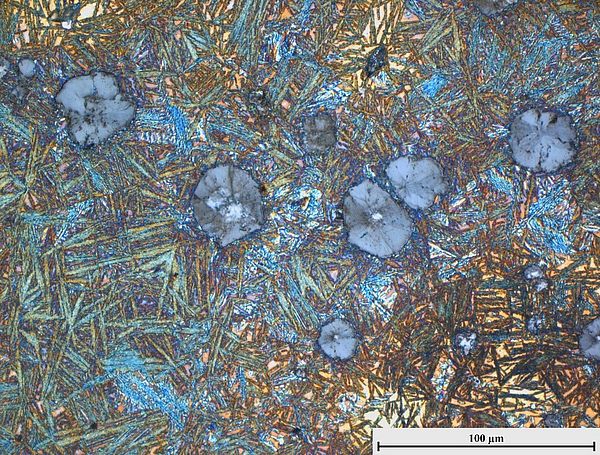

ADI for thick-walled components

The aim of the project is to establish an innovative strength verification method for use with components made of ausferritic cast iron with nodular graphite (ADI), in which the locally acting stresses determined from geometry and external loads are compared with the strengths locally present in the component and evaluated in a damage calculation. In cooperation with the Institute for Mechanical Plant Engineering and Structural Durability (IMAB) of the Clausthal University of Technology, thick-walled components and components with large wall thickness transitions made of ADI are to be characterized with regard to their microstructure, quasi-static and cyclic properties. The local microstructures in ADI components are to be predicted by process simulation and, by selecting suitable microstructural parameters, a material model is to be created for the first time that allows the local fatigue strength in the component to be predicted. As a result, even incompletely ausferritized components with inhomogeneous microstructures can be evaluated in terms of their fatigue strength. The results of the microstructure and property simulation are linked to the post-processor for service life estimation.

The direct benefit is that the concept and the tools created for it enable SMEs with one-off production and small batches in particular to evaluate the fatigue strength of components despite inhomogeneous microstructures without any experimental effort. The lifetime concept can significantly reduce the time and cost of component development and optimize component geometries in the direction of lightweight construction. The possible reduction in the use of expensive alloying elements such as nickel or molybdenum, particularly in the manufacture of thick-walled components, not only allows material costs of up to 30% to be saved, but also avoids grain boundary increases caused by Mo, thus achieving improved mechanical properties. The competitiveness of components made of ADI is thus increased compared to its alternatives, allowing existing business areas to be expanded.

Duration: 01.01.2021 - 30.04.2023

Project partners:

- Institute for Mechanical Plant Engineering and Structural Durability of the Clausthal University of Technology

- Iron foundry Hans Dhonau e.K.

- Josef Brechmann GmbH & Co. KG

- Buchholz & Cie. foundry GmbH

- Kessler & Co. GmbH Leipzig

- RWP GmbH

- Magna International Inc.

- ADI Technology GmbH

- Roll foundry & Hartgußwerk Quedlinburg GmbH

- Hawle Guss GmbH

Funding: German Federal Ministry for Economic Affairs and Energy

Responsible: Patrick Lachart